Dewetting of Metals

Thin metallic films are typically not stable on oxide surfaces. Thus upon increasing the temperature dewetting will start which finally leads to individual nanoparticles. We study such dewetting processes after a temperature increase induced by a nanosecond laser pulse.

Dewetting of nanostructures

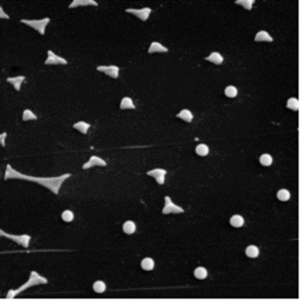

Upon illumination of individual nanostructures (e.g. triangles) with pulsed light the material will melt at a material-dependent threshold energy density. Immediately after melting, the liquid has a contact angle far from equilibrium and thus surface tension rearranges the liquid towards the equilibrium contact angle, which is close to a sphere. This transformation process (flat molten nanostructure towards liquid sphere) which can be seen in the image below happens on a timescale of few nanoseconds. As one can already suspect from the image this transformation is accompanied by an upward-movement of the center of mass. This leads to the jumping of the nanodroplets off the surface with velocities in the range of tens of m/s.

Dewetting process induced by a nanosecond laserpulse imping on Au-triangles on graphit. The energy density increases from upper left to lower right.

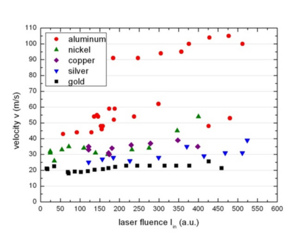

Particles are removed from the surface due to the dewetting process. The energy density increases from the lower left to the upper right.

The velocity of the jumping nanodroplets is almost independent of the laser energy density used.

Dewetting of continuous thin films

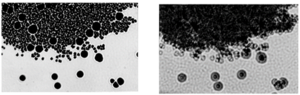

For a continuous thin liquid film the dewetting process is more complex. Typically two different routes can be observed, either by nucleation or by spinodal dewetting. This can be observed in pulsed laser illuminated metal films. Characteristic for the spinodal dewetting is the appearance of a characteristic wavelength which can be seen in the lower part of the right image. Nucleation on the other hand appears on already existing inhomogeneities in the film and thus arises earlier, which corresponds to lower energy densities for laser experiments.

Optical microscopy of laser-annealed Au thin films (left focussed, right slightly out of focus). The laser energy density increases from bottom to top. Big holes are formed by nucleation, the small scale surface corrugation on the right image by spinodal dewetting

Dewetting by laser interference

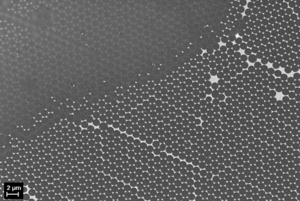

Upon illumination with a pulsed interference pattern the melting threshold is exceeded only in the high intensity regions. Thus the dewetting process is restricted to these areas. This allows producing periodic structures of various kinds, given by the details of the laser interference pattern.

SEM-images of dewetted metals films upon illumination with a two-beam (left) and three beam pattern (right)